MIE

The Fabric Printing Factory (MIE) is a company specialized in printing textiles for home furnishings. It collaborates with prestigious fabric editors such as Pierre Frey, Ralph Lauren Home, Braquenié, Le Manach, and Cowtan & Tout. What sets it apart is that it is the last company still practicing flat-frame printing, a traditional and highly skilled technique. This allows MIE to manage the entire production process in-house, without outsourcing. In other words, MIE controls every stage of creation—from design and frame preparation to final printing—ensuring exceptional quality and authenticity in its products.

The Frame Printing Technique

Until the late 17th century, textile printing was done using carved wooden stencils, commonly referred to as “blocks.” Carving a block required extreme precision and could take several months. This method was replaced in the 1940s by what is known as the “Lyonnaise” or flat-frame technique. MIE adopted this screen-printing tool as early as 1937.

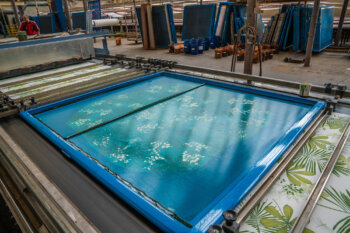

Unlike block printing, which allows multiple colors on a single plate, flat-frame printing requires a separate screen for each color in the design. It demands exceptional precision and coordination between the printmaster and the table chief. Using a squeegee, both printers apply each color to the fabric in perfectly synchronized movements—one pass for each color in the design. Some patterns contain over 25 individual colors, making this a truly unique expertise.

The final step, called “steaming,” consists of drying, finishing, and permanently setting the dye into the fibers to ensure exceptional colorfastness and durability.

Dyes and Materials

The Fabric Printing Factory uses only natural fibers: cotton, linen blend, pure linen, wool, or silk. When raw fabric arrives at the factory, it is not yet suitable for printing. It must undergo several treatments, including:

-

Singeing, which burns off any loose surface fibers,

-

Bleaching, which removes natural pigments from the raw fabric.

Printing is always done with vat dyes, selected for their superior fixation properties. These dyes offer excellent resistance to washing, dry cleaning, and light exposure.

Our most renowned clients include Pierre Frey, Braquenié, Le Manach, Cowtan & Tout, Ralph Lauren Home, and Brunschwig.

MIE is one of the last remaining hand printers in the world. This so-called “wet-on-dry” technique ensures flawless quality with no limit on the number of colors used.

Machine printing is used for designs with fewer than 20 colors and with a smaller repeat pattern.

The fabric undergoes more than fifteen pre- and post-printing treatments. Here, the stenter ensures the fabric is perfectly aligned with the grain.

Steaming brings out the colors and fixes them, making them colorfast (“grand teint”) for lasting durability.

Six control stations monitor the production process to ensure impeccable quality throughout.